We have set up our Barvala, Morbi-Navlakhi highway, Dist Morbi Gujarat.INDIA

The plant is equipped with latest machinery with optimum quality and performance that can match international stadards. The advanced machines and well-trained work ofrce enable us to execute all the tulk orders with perfection within stip wated time farme.

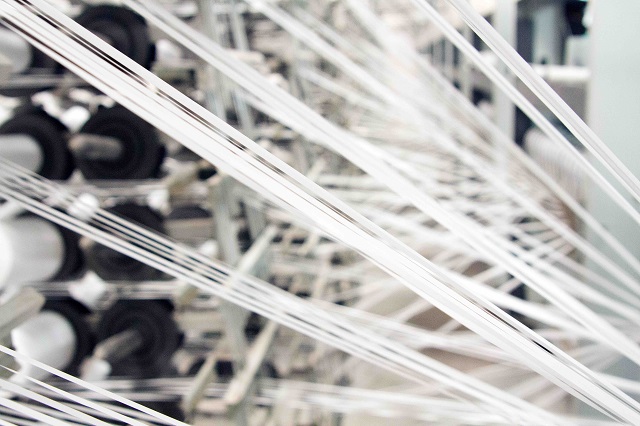

Earlier to 1984, blown film technology was used by sacks making industries, which was having capacity to covert HDPE using blown film technology, with 35~50 kg. / hr. output. Many sack-manufacturers slowly switched from blown film line to flat film line technology introduced by JP Industries, using coat hanger die / turn bar system as a conversion kit to replace old technology to new flat film. This innovation doubled the production and it was capable to run PP/HDPEraw materials.

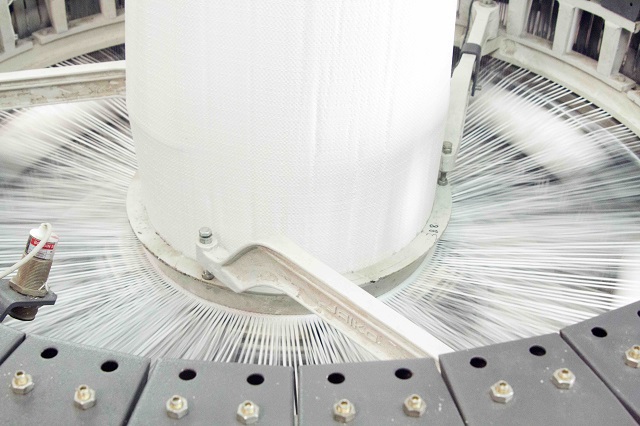

Our extrusion line, is the latest technology, like a blessing for the woven sack manufacturers. It is flat film line technology machine. This high-tech plant has capacities to manufacture bulk-bags up to 3000 kg.

Sustainability and Corporate Social Responsibility

Corporate Social Responsibility at Loyal Polypack Pvt. Ltd.; adheres that beyond making profits out of corporate world; we are equally responsive for totality of influences upon company’s stakeholders, its employees, customers, suppliers, vendors, government, community and the planet. We do believe that we have to be socially responsible, in order to stay productive, competitive, and relevant in a rapidly changing business world by relying on translucent business practices that are based on worthy values, by complying legal requirements, respect for environment, communities, and the customer.

At Loyal Polypack Pvt. Ltd. we believe that the interests of the business, the environment and our community must be addressed in balance to develop meaningful and effective sustainable solutions. We approach sustainability through a triple focus, incorporating Environmental, Economic and Social considerations.

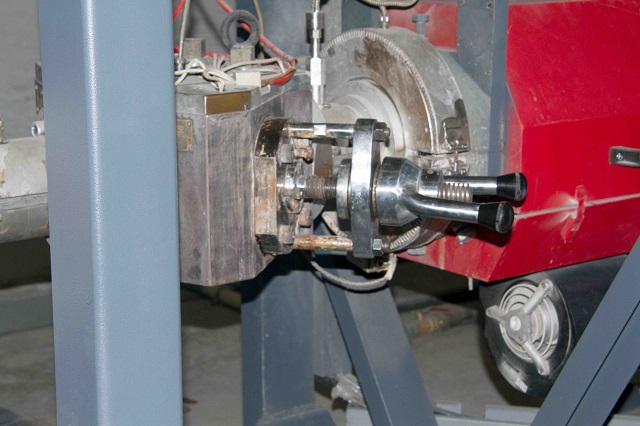

OUR MACHINERY AT GLANCE :

- High Speed Extruder with Capacity of 450 kg / hour.

- 42 Circular Weaving Machines.

- Auto Online Flexographic Printing Machines.

- Lamination Plant.

- Automatic Bag Cutting and Stitching Machine.

- 2 Manual Flexographic Printing Machines.

- Double Needle Chain Stitching Machines.

- Hydraulic Bale Press.

- Quality Testing Machines Like Tensile Testing Machine, M.F.I Tester.